Freezer Rebuild

I’ve completed rebuilds on ice boxes on a variety of Island Packets but until recently have not had a proper forum where I could go into sufficient detail on the process. I just undertook the rebuild on an IP-38 and will detail the process here for anyone interested in the method, materials, etc. Note that this method involves lining the existing compartment with extra insulation – not the complete removal of the old tub and foam and a rebuild from scratch.

I was originally commissioned to remove old foam insulation and reline the freezer and reefer compartments on this boat. However, very early in the project the old Glacier Bay holding plate system suffered a catastrophic failure and the project expanded to include the removal of all of the old system, redo of the existing box and then installation of a dual compressor Frigoboat keel cooled system.

I spent several days removing the old system to include ruptured holding plates, completely corroded heat exchanger, and cleaning up the area where the old compressor and motor had been installed. After cleaning out the old system and cleaning up the mess left behind I started removing left over insulation in the box. I used a Multimax cutter to remove the old IP foam holder in the overhead area of the box and then used spray foam to fill every void I could find.

| List of material: R-Max Polyiso insulation FRP shower liner Great Stuff spray foam 3M Series 80 spray adhesive 1/4″ hardwood plywood 1/2″ hardwood plywood Teak strips (1/2″ square) Piano hinge 1 1/16″ West System epoxy, hardener, white tint Formica and adhesive 3M 4200 fast cure assorted screws, tywraps, blue tape, etc |

| Parts: Frigoboat flat plate evaporators Frigoboat K-35 and K-50 compressors Merlin Smart speed control modules Coastal Climate Control digital thermostats Frigoboat keel cooled condensers LED light clusters (2) |

| Tools: Multimax cutter 1 1/2″ hole saw 1.5″r PVC bending mandrel cordless drill box cutter sharp knife trim router |

| Misc: #10 wire 15 amp circuit breakers terminal lugs 1″ starboard strips cut on a 45 degree angle |

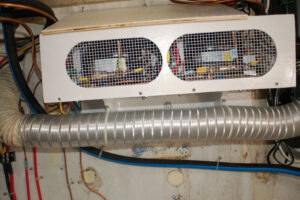

After cleaning up the old box and lazarette I installed the two keel cooled condensers and compressors. SInce the lazarette is used to store misc boating material I also provided a protective enclosure for the compressors. I added insulation to the inside of the box, build a divider and relined the interior with fiberglass panel. The starboard side of this box had already been foamed by a previous owner so my goal with this system was to provide a minimum of 1″ of new foam on all sides, 2″ on the top and make new doors to fit with 2″ of foam and rubber gaskets. In the IP-38 the box has molded in shelf brackets so I filled these areas with 1/2″ foam – metal side facing out. I cut the R-Max insulation to fit these areas, did a dry fit then when satisfied sprayed the inside of the box and the metal side of the foam with 3M adhesive. After letting the adhesive cure I press fit the pieces of foam.

The final part of this project was to bend and install the flat plate evaporators, make new rear hinged doors, install the thermostats and complete the wiring.